Praga was the first button company in India and it was established right here in Coimbatore

Buttons were first made in India about five thousand years ago in the times of the Indus Valley Civilization. In Coimbatore it was a little later when Joseph Nejedly, from Czekhoslovakia, came to India to work for Bata. He took up Indian citizenship, moved to Coimbatore and worked with P.S.G.Ganga Naidu for a while. Subsequently, he started a button company called Praga Industries Limited in 1945. The company started with the production of coconut shell buttons exclusively for defence use. By 1946, Praga began to make buttons made of vegetable-ivory buttons for others. By the 60s the production reached more than half a million buttons per day. Later, the company established a technologically advanced plastic button manufacturing plant.

One A.K.Annaswamy marketed the Praga buttons that was the largest button company in this part of the country. Eventually, the company produced fibreglass boats too. Joseph Nejedly and his family lived in a beautiful bungalow on Race Course and he was a popular member of The Coimbatore Club. He was also the first to produce helmets for the army and was awarded a medal for the same.

Those days there were about 20 button companies in India and they were located in Amritsar, Coimbatore and Kolkata. Our country attained self sufficiency in button production within the first 10 years of independence. There were five factories in Coimbatore alone and they could altogether produce million buttons a day.

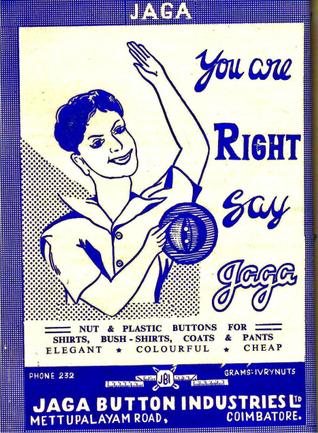

S.Kondaswamy, was the second entrepreneur who started Jaga Buttons in Coimbatore. He was working for the Rajapalayam Textile Mills as Manager. He was the promoter of Subbiah Foundry, Madras Forgings and a spinning mill later along with his relatives and his sons Subbian, Jagannathan. N.Subbian who is in his 80s now was the marketing man of Jaga Buttons. He says, “We sold buttons in Mumbai, Kolkatta, Chennai and important commercial centres such as Vijayawada. Andhra was a good market. We supplied goods on a 15 day credit and discount the bills with our bankers Indian Bank and Karur Vysya Bank. Buttons were made in more than hundred colours and the colour pigments were from companies like ICI. We sold to outlets like Bharat Button House in Coimbatore. However our biggest market were the defence services who picked up over ninety per cent of our production. We made olive green buttons for the army and blue buttons for the navy. These buttons were fixed on the defence uniforms at the Shahjahanpur factory in Uttar Pradesh. The orders were through sealed tenders submitted with the Directorate of Supplies and Disposals located at the Fort in Mumbai.

The Inspectorate of General Stores used to inspect the factory. The buttons were randomly tested in boiling hot water for colour and by hanging weights in order to ascertain the strength. Payment was made only after the buttons passed these tests.” .”

Vijaya Industries which was located near the Railway station in Peelamedu was another leading manufacturer who set up shop in the year 1951. It was managed by N.Duraiswamy, and K.Venkatesalu of Ellen Industries was the promoter of this company.

Later competition came in the form of small button facilities that came up at Bengaluru and also in the form of companies such as Ratanchand Harjas Rai of New Delhi whose huge production facilities at low prices were a dampener for others in this field. But the button industry at Coimbatore continued to thrive thanks to the entrepreneurial zeal of its people.

source: http://www.thehindu.com / The Hindu / Home> Features> MetroPlus / by Rajesh Govindarajulu / February 28th, 2015