Anjali Srinivasan was recently selected as one of the ‘Swarovski Designers of the Future’. The glass-smith from Chennai talks about art as an invitation to dialogue, sustainable design and her vision for future living

To Anjali Srinivasan, the kiln is where the art is. It is where the familiar meets the imagined, where strength courts fragility and where physical forms signal ephemeral experiences. The idea of working with red-hot molten material, and learning to control it as it transformed from solid to liquid and back to solid, unfolded when she visited Firozabad, India’s glass hub, during her student days at the National Institute of Fashion Technology.

Anjali’s sense of inquiry about the medium took her to Alfred University in New York and the Rhode Island School of Design, where she invoked new ways of working with glass. ‘Puffy Glass’, one of her many inventive departures, was the outcome of “intensive research in particle activism”.

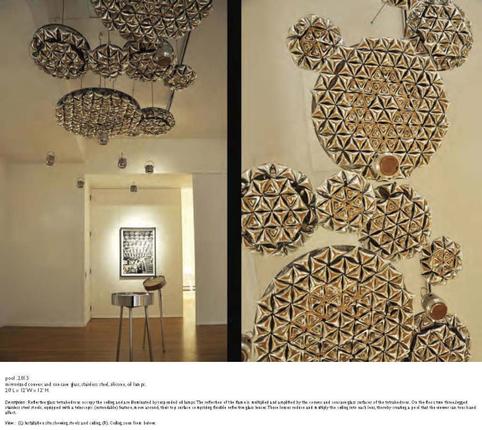

Back in India in 2010, she worked with traditional glass artisans in Firozabad, Purdilnagar and Papanaidupet, before setting up a studio in SIDCO Women’s Industrial Park near Pallavaram in 2011. With ‘Depths of Field’, where she showcased a wearable glass sculpture and an installation that sprayed turmeric and coffee into the gallery when a participant pulled at its strings, and ‘Of Shifting Natures’, the highlight of which were digital prints on flat glass and a mirror-painting diptych encrusted with tiny convex mirrors that turned the viewer’s movement in front of it into its subject matter, Anjali subverted preconceptions of her medium. After many solo shows and honours, she moved to Dubai last year “as a random life experiment”, and set up ChoChoMa Studios, where she provides customised solutions in hand-crafted glass and conceptualises themes for art shows. It was during a showing at the Dubai Design Week last year that ‘Untitled’, an 11-ft high archway with web-like glass filaments co-constructed with visitors, caught the attention of the Swarovski-Design Miami/Basel team scouting for convention-challenging talents.

In an e-mail interaction, the artist talks about the honour and the less-trodden paths her work is leading her to. What you cannot ignore is the fact that to this artist, the glass is only half full — always!

What did the Swarovski selection panel find unique about your work?

They informed me that I had been selected through a nomination process. The curator felt that my approach was worthy of recognition, as it showed a new way forward for creative process and its engagement with people.

Since it’s a Swarovski honour, would the assignment involve working with crystals?

The award comes with a commission, and so yes, I will be working with Swarovski to create something new for Design Basel in June 2016. Who knows what the future holds past that, but since I am interested in optical phenomena, and crystals epitomise optics, I hope to continue using crystals.

The optical behaviour of crystal is quite different from glass…

For me, the task of working across media lies in being able to speak in the voice of each material, and bring out a conversation or collaboration between them. I see harmony as just one theme in design. Sometimes, the communication of diversity, tension or even conflict between media helps in the effectiveness of a work.

Going by your repertoire, it’s apparent that art is part of the dialogue in any interior space you create…

I am foremost an artist; it is about how I see the world and relate to my existence. My design practice feeds into building that overall philosophy, and I am fortunate to be able to interpret interior spaces in that sense.

You’ve used spices, dough, coffee powder at shows… What are your latest experiments?

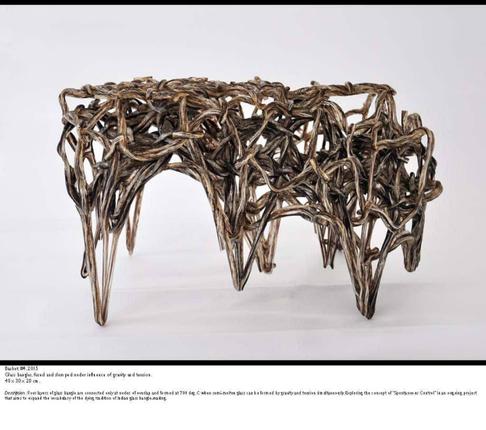

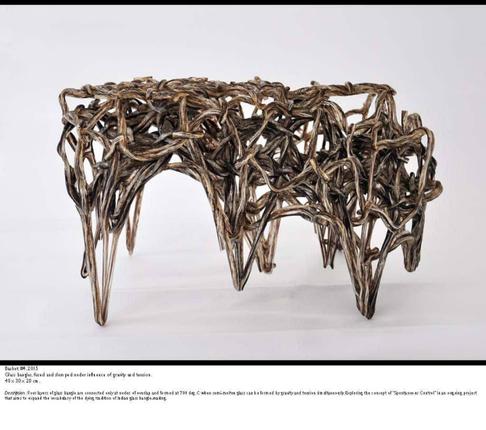

I’m working on transitioning from a crusty, rock-like glass entity to a sublimated, light-infused crystal body, all in the same object. I hope this investigation can be used in the Swarovski project. Simultaneously, I am looking at expanding the material language of glass bangle-making. I want to build a new vocabulary that sustains the craft tradition across its current boundaries.

What drew you to Dubai?

I realised that living and working in my home country was not conducive to my practice. Also, I had outgrown the job market in the U.S., from where I had relocated to India. I looked for some place in-between India and the U.S. My gallerist was showing works at Art Dubai with significant success. It was a random life experiment to see what it is like to set up a creative enterprise in Dubai.

What led you to launch ChoChoMa? In what way has the studio pushed the frontiers of glass and nurtured craftsmanship?

ChoChoMa Studios is named after my grandmother. It was started originally as a fair-trade umbrella for glass artisans I was working with in Delhi in 2005. The goal was to upgrade technology, offer design inputs and guide artisans to sell directly to consumers. I wanted the handicraft glass sector in India to have a voice in creative activity. But, since then, its role has changed, according to what I responded to most. We showcased contemporary art collaboration with traditional artisans during Art Chennai in 2014. Today, we are a start-up in West Asia, working on design projects, teaching students about glassmaking and making impossible ideas happen through art.

Yes, it has been an important concern of the Studio. We just created tableware for a restaurant, by splicing old water bottles. We are working on large wall panels that use bottle glass, for a city-wide recycle centre initiative of the Dubai Municipality. Each panel saves 50 kg of consumer glass from landfills — a heartening application of sustainable design.

What is your vision of future living? Where do you see your medium going?

My vision is less dissonance between humans, and humans and their objects. Creative glass exploration, with recent developments of 3D printing and lathe-working, is heading towards breaking traditional boundaries with technology, as well as being a medium of performance, time and phenomenon-based interfaces.

Three names were announced by Swarovski (including a two-member design team). In what way do you think your work will be different?

I’d like to believe that each of our works will be special, based on our vastly different backgrounds. I am the only artist in the lot. So, my approach will be more conceptual and I will explore the philosophies I am invested in. I was told that I am the first Indian designer, and also the first glass-maker chosen for the honour. I have been encouraged to use my own glass in collaboration with crystal, so I imagine that will define the project as being unique. My sensibilities are Indian, my skill-base is American, and I am working out of West Asia and imagining with Swarovski crystals! Surely that adds up to something significant, right?

source: http://www.thehindu.com / The Hindu / Home> Features> MetroPlus> Society / by T. Krithika Reddy / March 22nd, 2016